SVETLANA PANASYUK

Medical Hyperspectral Imaging

Optical Metrology

Tissue Spectroscopy

Mantle Flow

GPS

Remote Sensing

Image Processing

Fun

Reference Earth Model

|

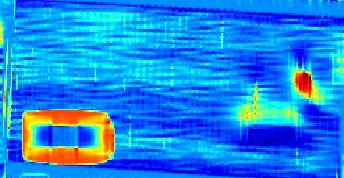

Accordion Fringe Interferometry (AFI) is a revolutionary technology that applies

linear laser interferometry to three dimensions. It allows to make a 3D digital

model of a subject as easy as traditional photography. The original work on AFI

was done at the MIT Lincoln Laboratory - Federally Funded Research and Development

Center of the Massachusetts Institute of Technology (MIT). All of the MIT-developed

AFI patents are exclusively licensed by MIT to DPI for all fields-of-use worldwide. One of the unique applications of the AFI technology is Quality Control

of large objects in fast moving assembly lines. the AFI technology allows to

detect and visualize an anomaly or an abnormality in composites that are

dimensionally within tolerance. For example, a tiny dent on the car's door that becomes visible only at certain angles. During assembly, such a defect will usually be missed and discovered only at the final sar assembly inspection. With the real-time image processing techniques, such a dent can by visually amplified and the failed part to be removed earlier from the assembly line. Here is an example of such dent detection next to the door handle:

Work was done while at DPI: Dimensional Photonics |

Anomaly Detection

Anomaly Detection